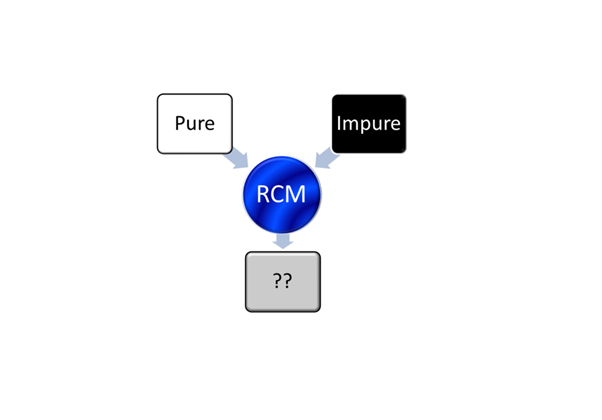

Any reliability-centred maintenance (RCM) practitioner worth their salt will be able to wax lyrical about how vital understanding the operating context is to a successful analysis but…

What of the context of the RCM study itself? … The motives behind launching an RCM activity can influence the way in which a study is conducted and, ultimately, degrade the final product.

Maintenance is an investment. It is the investment that an organisation makes in order to maximise the potential of its equipment and RCM is a tool that determines the activities in which they should invest in order to ensure the safe and efficient operation of it.

When applied with pure intentions an RCM study will identify where that investment should be made, either as a one off cost through design change or as a regular cost through maintenance.

But…if the motives aren’t pure; if the motives are tainted by misunderstanding or assumptions such as:

- ‘it’ll reduce maintenance costs’

or

- ‘it’ll validate what we already do’

or

- ‘we just have to’

or

- ‘it’ll check how our equipment is performing against the contracted requirements’.

could those misunderstandings or assumptions influence the analysis itself?

RCM provides a solid framework within which an analysis can be performed but the subjective nature of the information that is used to populate that framework, from effects through to management strategies, can leave a lot of wiggle room and wiggle room can be exploited by influence.

It’ll reduce maintenance costs

If a study is kicked off with this stated aim, then it will either lead to disappointment (because that’s just not what it does) or it could influence decisions to the point where the outcome is optimistic, bordering unsafe, or actually more expensive when the bigger picture is considered.

It’ll validate what we already do

I’ve seen this. Using ‘RCM principles’ – whatever that means in this context – to justify the performance of the current maintenance regime. RCM is a ‘blank piece of paper’ methodology because that best enables the identification of emergent or just overlooked scenarios and suitable mitigation for them, it is not a validation tool and using it as such will limit the ability of the analysis to identify gaps or new needs. The outcome, at best, is maintaining the status quo; at worst the current regime may be further degraded.

We just have to

This is an interesting one and one that is seen pretty often. RCM, in this case, becomes an annoyance – a seemingly expensive one – and while it may not necessarily affect the way in which the activity is completed, it will certainly affect the willingness to adopt the findings. If RCM is seen as a ‘tick box’ exercise there will be reluctance to implement change resulting from it.

It’ll check how our equipment is performing against the contracted performance

This was put forward, recently, by an organisation that should know better. Nope. Just no; RCM does not do that.

RCM isn’t about reducing maintenance costs, doing less, ticking boxes or making comparisons. It is about understanding.

RCM will help an organisation to understand what can happen, what it could mean and what could be done about it but, it can only do those things if it is allowed to; if it doesn’t have to battle a hidden agenda.

About the Author

Lee is a Director and support engineer with Aspire Consulting. He is the product lead for Aspire’s reliability-centered maintenance and training development services and acts as the focal point for Aspire’s involvement in the Pierian Academy.

Connect with Lee on LinkedIn

About Aspire

What does Aspire do? Almost every organisation on the planet uses equipment to deliver its service. Very few are always

happy with the performance of that equipment. We train, guide and

collaborate with organisations to design support solutions that keep

equipment performing, so they can deliver their service, consistently and

effectively.

Follow Aspire on LinkedIn